Hotline:+8615963413641

Hotline:+8615963413641 Inquiry

InquiryRadio shuttle racking system introduction:

(1)Concept:

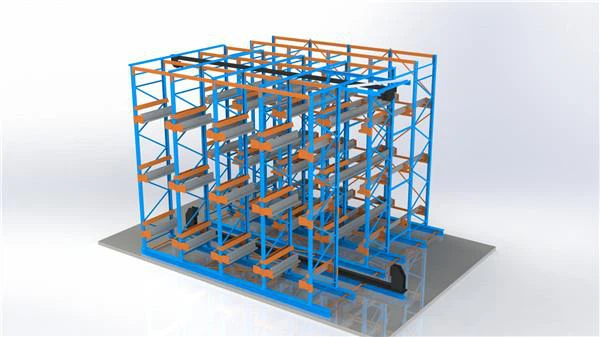

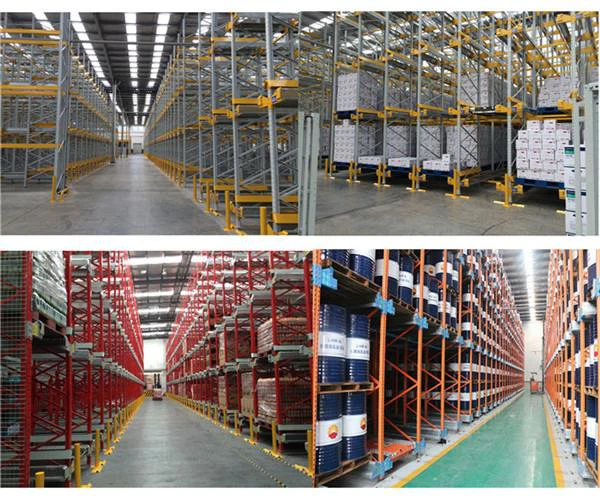

Radio shuttle rack system consists of supporting rack, guide rail and a radio shuttle car. The Radio shuttle car runs on the rails and is propelled by a remote control. It also has a platform on the top that can lift up and down. The lifting action is required to lift a pallet that is placed on the rail and then the remote control moves the car with the pallet on top into the rack in order to place the pallet on its right position.

Operation mode:

Radio shuttle rack with forklift and workers divides storage and transportation of pallet, and radio shuttle car do the storage of pallet by wireless. Forklift and workers complete transportation of pallet. No need enter storage area, forklift works on the front of storage area , and the pallet will be taken to designated location by radio shuttle car. Pallet storing instruction is sent through wireless remote control by operator, who can also terminate the action being executed. The first location on the front of rack is the location for forklift to pick and put pallet,

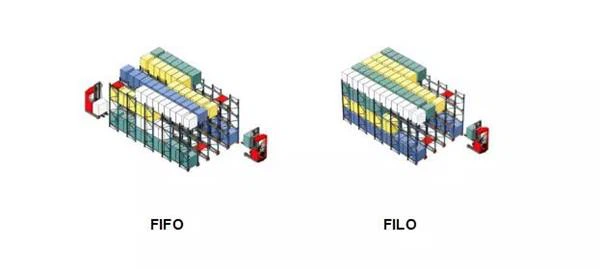

When the pallet is required, the car moves under the pallet, lifts it and brings it to the front of the rack where it can be retrieved by a forklift.All the movements of the shuttle car are controlled with a hand held remote control. The shuttle car is placed in the desired aisle with a forklift.Two working modes such as first-in-first-out and first-in-last-out can be selected.

Advantages:

•Efficient load and unload system, which ensures high accuracy.

•Goods can be stored in the warehouses with highest density and low cost.

•Less damage to the rack as the forklift does not enter the racking unit.

•Better safety and anti-seismic performance than drive in racks.

•Greatly reduced labor cost.

•Compatible with different pallet sizes.

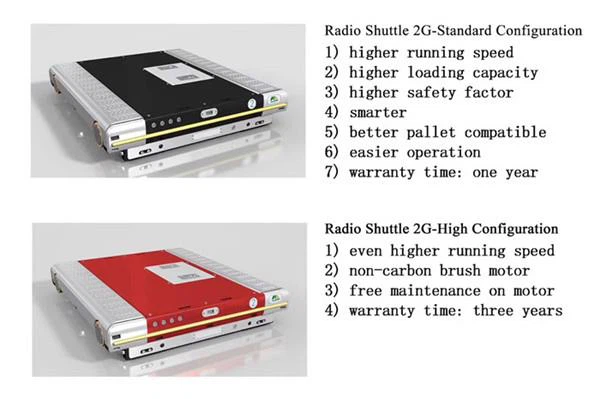

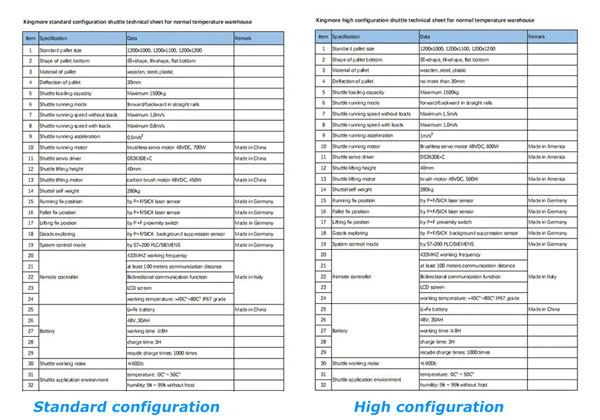

Specifications:

Products show:

Packaging & Delivery

Packaging Details:

(1).Standard package: frames, box beams and shelves are packed by steel belt and covered by plastic film;bolts and nuts are packed by cartons.

(2).Package can also under customer requests

(3).As package size un-standard each time, will let client know how many sets can be fit in one container

Port: Nanjing; Shanghai

Lead Time :

Quantity:1*20ft container/1*40ft container takes about 3 weeks production time.

Many containers to be negotiated.