Hotline:+8615963413641

Hotline:+8615963413641 Inquiry

InquiryIntroduction:

Drive-In Rack is a kind of high density storage system. A simple way to identify a Drive-In Rack Systems is its FILO inventory management. Product is rotated in a FILO inventory manner because of the single entry/exit point. Typically, Drive-In racking requires operators to drive into the racking system from one side and remove pallets from the same entry point. Some Drive-In rack systems have a wall or are otherwise closed at the opposite end.

Features:

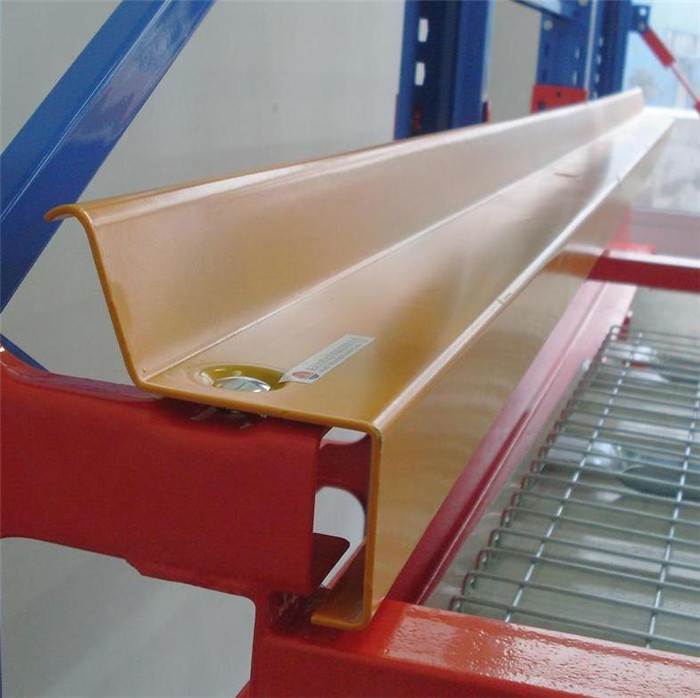

1) .On the support rails, the pallets are stored in depth one by one, which makes the density storage possible.

2).The goods are accessed from the same side of the rack. The counterweight and reach truck can easily access the shelf to access the goods without occupying multiple channels.

3).This kind of rack is suitable for storage of high-volume, low-variety items. The leg and leg shelves of drive-in racking are all made of integral stamping/rolling technology, which has strong bearing capacity and beautiful appearance.

4).Drive in racks are all plug-in assembled structures. Columns are fabricated. The total depth of shelves in the wall area is preferably controlled within 5 pallets depths. The total depth of the shelves in and out of the middle area is generally controlled to 10 pallets depth to improve the efficiency and reliability of forklift access.

Advantages:

1).The cargo storage channel is also a storage and transportation channel for forklifts. It is a type of rack with a high storage density.

2).Often used for cargo storage where the variety is small but the batch is large and the cargo picking requirements are not high.

3).Taking the elevation of common forklift trucks and the conventional plan for the number of shelves in the corridor as the three-tier cargo, the effective storage capacity of the warehouse can be increased by more than 100%. In contrast, the investment cost is controlled and the benefits are significantly improved. From the overall storage cost calculation, generally increase the storage capacity in three years to offset the investment cost

Main constitute parts:

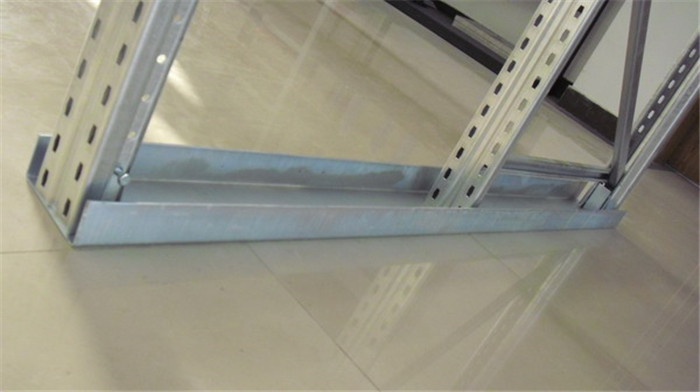

1).Frame

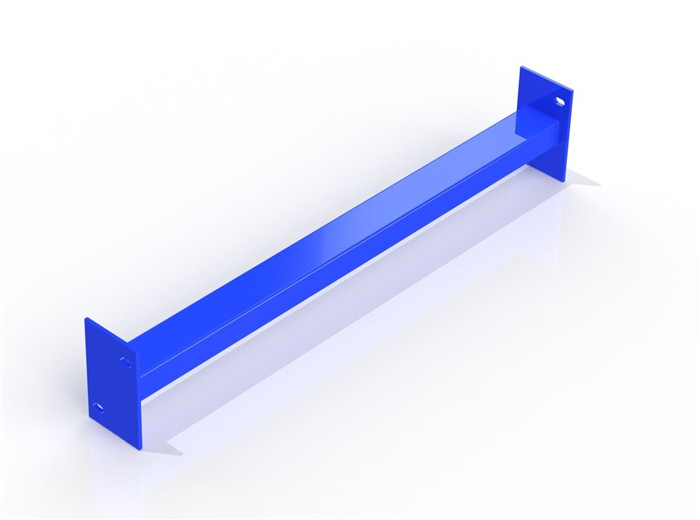

2).Row spacer

3).Pallet rail

4).Double side arm

5).Single side arm

6).Top beam

7).Back beam

8).Top bracing

9).Back bracing

10).Guide rail

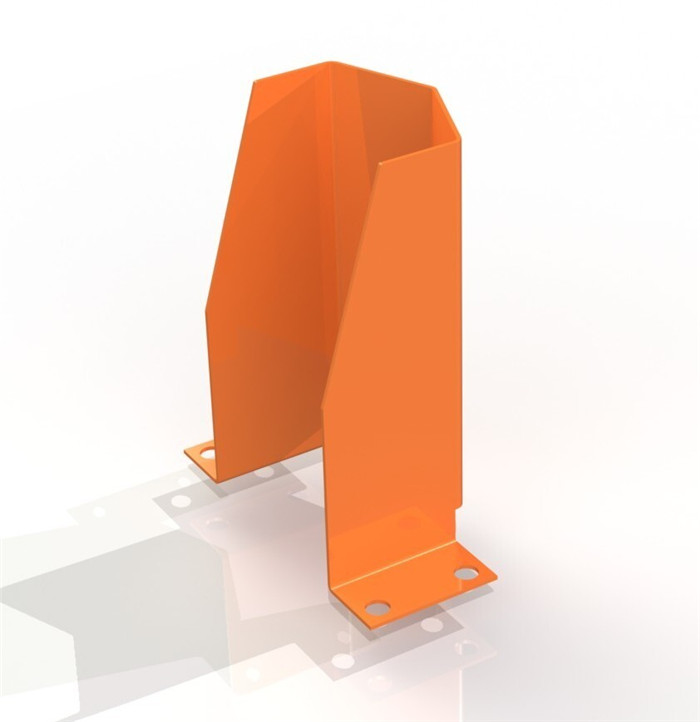

11).U shaped upright protector

Application:

We are the most professional racking manufacturer in China. We have done many drive in racking projects. These are some pictures of some projects about drive in rack.

Packing and shipping:

1).Packaging details:Standard export package.All parts packed by steel belt and covered by plastic film.

2).shipping time: 3 weeks after receipt of the 30% deposit.